Industrial furnace thermocouple installation methods

Keywords:Industrial furnaces, thermocouples, installation, accessories

Industrial furnace thermocouple installation methods

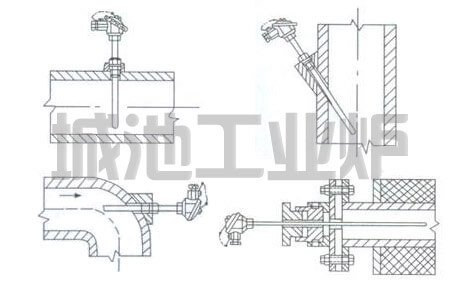

The figure below shows several mounting forms thermocouple, thermocouple in forging shop in the wider application. But in a larger vibration forging shop, take anti-vibration slots facilities, to avoid affecting the accuracy of the instrument. Thermocouple advantages are: Gao can accurately measure the temperature, the error is ± (2. 4~4) "C> If you connect automatically records and automatic control of the thermocouple millivolts or potential difference, not only to direct seen at the time of temperature, but also it can be seen a temperature change (on a moving tray or tape formed with time-dependent temperature curve>. The disadvantage is that the thermocouple measured temperature furnace, without considering and the temperature of the heating furnace to a temperature difference between the metal and therefore folios to infrared exhaust Thermometers to when used in combination.

Industrial furnace thermocouple installation methods

An industrial furnace thermocouple installation and maintenance training

1, learn to use a thermocouple, RTD temperature measurement;

2, master installation method thermocouple and thermal resistance;

3, grasp the connection method thermocouple, RTD and secondary instrument.

Second, industrial furnace thermocouple selection

1, the measured object temperature range chosen RTD.

2, the temperature distribution of the measurement value of an object selection thermocouple.

Third, industrial furnace thermocouple installation requirements

Industrial furnace thermocouple installation, you should pay attention to temperature conducive to accurate, safe, reliable and easy to maintain, and does not affect equipment operation and production operations. To meet the above requirements, the choice of the thermocouple and RTD's mounting position and insertion depth To note the following:

1, in order to measure the end of the industrial furnace thermocouple sufficient heat exchange between the measured medium, should be a reasonable choice of measuring point to avoid dead ends in the vicinity of valves, elbows and piping and equipment installed thermocouple or resistance.

2, the industrial furnace with a protective sleeve thermocouple heat transfer and heat loss, in order to reduce measurement error, thermocouple and thermal resistance should have sufficient depth of insertion: 2.1 for measuring the temperature of the thermocouple central fluid conduit, generally should The measurement end into the pipe at the center (vertical or inclined installation installation) as measured fluid pipe diameter is 200 mm, then the thermocouple or RTD insertion depth of 100 mm should be selected.;

2.2 For high-temperature high-pressure and high-speed fluid temperature measurement (such as the main steam temperature), in order to reduce the protective cover of the fluid resistance and prevent breakage occurs in the protective sleeve fluid action can be taken to protect the pipe plug or by shallow thermal sleeve type thermoelectric . Even light plug-in thermocouple protection tube, insert it into the main steam pipe depth should not be less than 75mm; thermal sleeve thermocouple standard insertion depth of 100mm;

2.3 If you need to measure the temperature of the flue smoke, despite the flue diameter of 4m, thermocouple or RTD insertion depth of 1m can be.

2.4 When measuring the original insertion depth exceeds 1m, should be as vertical installation, or installation bracket and protective sleeve.

Fourth, industrial furnace thermocouple installation methods

1, we must first measure the thermocouple and RTD thread size, thread a good car seat.

2, according to the thread diameter of the seat, on the need to measure the pipe openings.

3. Thread the seat of welding. The thread insert seat has a good hole to thread the seat and pipe welding is a good measure.

4, the thermocouple or RTD precession has been welded thread blocks.

5, according to the wiring diagram of the thermocouple or RTD junction box wired and connected to the corresponding dial indicator. Note that the junction box can not be in contact with the wall of the pipe measured media, ensure that the temperature inside the terminal box does not exceed the range of 0-100 ℃. outlet hole junction box should be installed facing down, to prevent poor sealing, water vapor and dust deposition caused by short circuit terminals.

6, the position of industrial furnace thermocouple installation, easy maintenance and repair should be considered.

More Industrial furnace thermocouple installation methods:http://www.industrial-furnace.com/articles/thermocouple_installation.html

Pre:Principle of bright annealing ,Next:None