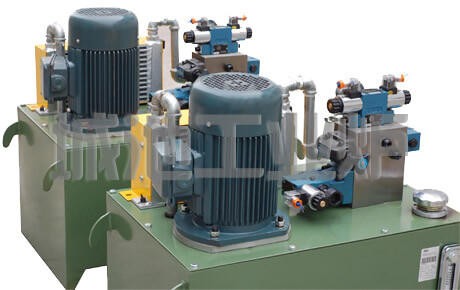

Hydraulic Station

Hydraulic Station

Also called hydraulic pump stations, pump stations, is mainly used for heat treatment industrial furnaces, furnace, quenching tank power system, usually used lifts, the door opens, Taiwan and other parts of the conversion. Hydraulic station

Abstract

- Promulgator: :industrial furnace

- Send date:2015-10-31 16:06

Keywords:Hydraulic station,hydraulic pumps,gear pumps,pump stations,li

Hydraulic Station

Also called hydraulic pump stations, pump stations, is mainly used for heat treatment industrial furnaces, furnace, quenching tank power system, usually used lifts, the door opens, Taiwan and other parts of the conversion.

Hydraulic station is by the hydraulic pump, drive motor, fuel tank, directional valve, throttle valve, relief valve and other hydraulic source device or apparatus includes a hydraulic control valve, including the composition. Drive required by the flow, pressure and flow supply, suitable for driving on various mechanical devices and hydraulic station separate hydraulic station and drive (cylinder or motor) with tubing connected to the hydraulic system can achieve a variety of provisions action.

Hydraulic station, also known as pump stations, motor driven rotary pump, suction pump from the tank after Dayou, the mechanical energy is converted to pressure of the hydraulic oil can be hydraulic oil through the manifold (or combination valve) is hydraulic valve to achieve a direction, pressure, After adjusting the flow through an external transmission line to a hydraulic cylinder or motor oil machinery, thus controlling the direction of the change was the motivation, strength of size and the pace, pushing all kinds of hydraulic mechanical work.

Hydraulic stations are independent hydraulic device which press drive device (host) requires oil and to control the direction of the oil flow, pressure and flow rate, which applies to the host and the hydraulic unit detachable hydraulic machinery, the oil pump driven by the motor rotary pump from the tank after the suction Dayou, the mechanical energy is converted to pressure hydraulic oil can.

Hydraulic station features:

Hydraulic pump means is, Manifold or valve combination, fuel tank, electrical box combination, the components function as follows:

Pump device - is equipped with motor and pump, it is the source of hydraulic power station, the mechanical energy is converted to power hydraulic oil can.

Manifold - is a combination of hydraulic valve and passage body from. Hydraulic oil to implement the direction, pressure, flow regulation.

Valve combination - plate valve is installed in the vertical plate after plate and pipe connections, and features the same manifold.

Tank - is a semi-enclosed container steel welding, the network is also equipped with oil filter, air filter, etc., it is used oil, cooled and filtered oil.

Electrical boxes - two forms: a setting external lead terminal board; one is equipped with a full set of electrical control.

Hydraulic stations:

1, the motor, gear pump - providing a driving force for the hydraulic system.

2, solenoid valve - controls the hydraulic oil flow direction, change the direction of movement of the cylinder.

3, the electromagnetic relief valve - prevent the entire hydraulic system overpressure, the equivalent of a safety valve to protect the safety of the oil pump and hydraulic system and hydraulic system to keep the pressure constant.

4, valves - by adjusting the valve body of work to meet the different needs of different working pressure requirements, the secondary line pressure is lower than a line pressure.

5, control valve - on the oil throttle speed, you can change the actuator operating speed of the hydraulic cylinder.

6, hydraulic oil filters - there are two hydraulic oil filter mouth. An installation at the suction port of the gear pump, hydraulic oil tank to prevent inhalation of the particles and other impurities. Another system installed in the hydraulic oil delivery pipeline, to clear impurities in the hydraulic oil, but also to clear the hydraulic oil itself gum produced by chemical changes, asphaltenes, carbonized particles and the like. Thus serves to prevent the spool stuck, orifice blockage failure. The pipeline system has pressure alarm device, when filter clogging, telecommunications issue number, you should clean or replace the filter.

7, pressure gauge - for displaying operating pressure of hydraulic station, in order to facilitate operator control oil pressure.

8, the air filter - installed on the tank, there is a triple role, first to prevent air pollutants into the tank; the second is the role played ventilation, avoid oil pump suction air phenomenon; Third cater hydraulic oil supply port.

9, oil level gauge - side mounted fuel tank, hydraulic oil level display.

10, thermometer - some equipped with thermometer on the fuel tank, hydraulic oil temperature display.

11, joins the line - the driving force of the hydraulic transport, most with steel, but also useful pressure hose.

More Hydraulic Station:http://www.industrial-furnace.com/furnaceaccessories/Conveyor_Transmission/hydraulic_station.html