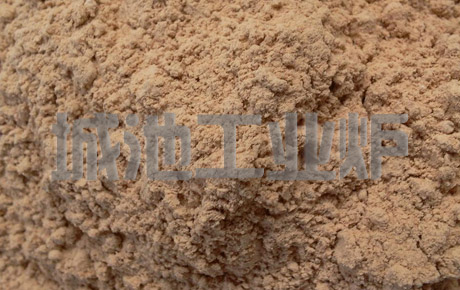

High-alumina refractory clay

High-alumina refractory clay

High-alumina refractory clay, also known as: high temperature refractory cement, refractory cement, refractory cement, high-alumina refractory cement, refractory mortar, fire clay, depending on the material can be divided into clay refractor

Abstract

- Promulgator: :industrial furnace

- Send date:2015-10-31 16:02

Keywords:Refractory mud,high-alumina refractory cement,refractory ceme

High-alumina refractory clay

High-alumina refractory clay, also known as: high temperature refractory cement, refractory cement, refractory cement, high-alumina refractory cement, refractory mortar, fire clay, depending on the material can be divided into clay refractory clay, siliceous refractory clay, magnesia refractory mud.

High-alumina refractory mud refractory powder, binders and additives composition. Almost all are made of refractory materials used to formulate refractory clay powder used. To add the amount of plastic powder clinker refractory clay as binder and plasticizer made of said common refractory clay, its low temperature strength, high temperature ceramic bond is formed that has the higher strength. With hydraulic, gas or hard thermosetting binding material for the water glass as binding agent, said chemical bonding refractory clay, which produce a certain chemical reaction before the formation of the ceramic bonding temperature lower than hardened.

Refractory clay particle size varies according to application requirements, the ultimate particle size generally less than 1mm, some less than 0.5mm or finer.

Refractory mortar material selection should be considered consistent with the refractory products masonry material. Clay refractory material except for masonry joints, but also can be used smear method or spraying method is used as a protective coating lining body.

The advantages of high-alumina refractory clay

1, plasticity, easy construction;

2, adhesive strength, strong resistance to corrosion;

3, relatively high refractoriness up to 1650 ℃ ± 50 ℃;

4. Slag Corrosion resistance;

5, the thermal spalling resistance. Refractory clay is mainly used in industrial heat treatment furnace, resistance furnace, gas stove, furnace, hot blast furnace, other industrial furnaces.

More High-alumina refractory clay:http://www.industrial-furnace.com/furnaceaccessories/Refractory_Insulation/refractory_clay.html