Through automatic continuous cleaning machine

Through automatic continuous cleaning machine

Automatic continuous cleaning machines by using chain drive or a belt drive mechanical transmission parts, having a cleaning, rinsing, compressed air, hot air drying and other features of the new cleaning equipment, has added during rinsing

Abstract

- Promulgator: :industrial furnace

- Send date:2015-11-01 08:57

Keywords:cleaning machines,automatic washing machines,automatic washin

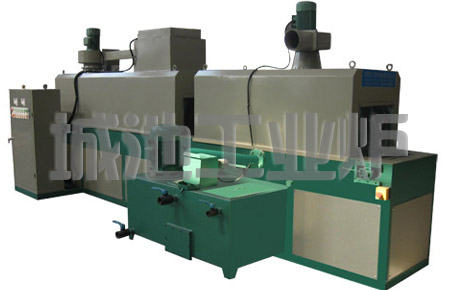

Through automatic continuous cleaning machine

Automatic continuous cleaning machines by using chain drive or a belt drive mechanical transmission parts, having a cleaning, rinsing, compressed air, hot air drying and other features of the new cleaning equipment, has added during rinsing bag fine filter, high filtration precision cleaning fluid, cleaning effect, high cleaning efficiency, easy to operate.

Network with automatic washing machine called the furnace with automatic mesh belt straight through type cleaning machine. But also become: heat washing machine, electric matching washing machine, furnace cleaning machines, belt cleaning machines, washing machines through continuous cleaning machines, by cleaning machines, automatic washing machine. By type washing machine is dedicated to supporting industrial heat treatment furnace production line cleaning process for heat treatment of various mechanical parts and components of an advanced cleaning equipment. Which mainly consists of cleaning spray, compressed air, etc., through the cleaning machine structure compact, handsome in appearance, complete functions, high degree of automation, good cleaning effect, continuous heat treatment production line for professional cleaning of the workpiece, especially for After quenching quenching tank, lifting belt up to the entrance through the cleaning machine, cleaning machine into the over-spray by washing, drying, directly into the network back to stove tempering process. Thereby enhancing the production efficiency of the whole heat treatment production lines.

Automatic continuous cleaning machine is used by a mesh conveyor continuous conveyor, nozzle disposed on the conveyor, down, left, right, predominantly clean ,, compressed air, clean rinse coarse filter, oil-water separator Automatic suction fog ventilation, the rinsing liquid is heated and automatic temperature control and other functions. Reasonable structure, stepless adjustable belt speed, and is equipped with adjustable angle nozzles, simple operation, easy to use, which is to improve the cleaning workers' working environment, improve the cleaning quality, has special significance.

Through automatic continuous cleaning machine is mainly composed of the device body and the tank, conveyor systems, cleaning systems, rinsing systems, compressed air systems, filtration systems, hot air drying system, automatic temperature control heating system, demisting systems, electrical control systems and other components.

1, the device body and the tank

1.1, the machine is fully enclosed structure, using welded steel skeleton, washing machine cover part of a single-layer structure, made of stainless steel plate 1.5mm thick (on request color spray paint), drying section set insulation and reduce energy consumption.

1.2, tank using a single layer structure, a 2mm thick stainless steel plate production (according to the desired color spray paint); internal separator is divided into several areas, namely to achieve the cleaning liquid filtration, oil filter, oil; tank provided There are water port, discharge port, overflow. Is inclined to the middle bottom sides, concentrated cleaning liquid is discharged from the discharge port of the tank bottom.

1.3, tank fitted with level controller, level abnormal timely reminder to pay, without water. Emergency stopping abnormal situation, and has sound and light alarms.

1.4, stainless steel tank equipped with an internal electric heater, in 30 to 60 minutes from room temperature to the liquid temperature. Automatic temperature control in the range of 10 ~ 90 ℃, manual setting, automatic control. With a temperature control instrumentation is automatically displayed.

2, delivery systems

System consists of cycloid reducer, conveyor chains, ribs, the main drive shaft is the drive shaft and other components. Bending plate chain conveyor with high strength, ribs be treated with preservatives. Conveyer belt speed 0.15 ~ 3m / min continuous stepless adjustable.

3, the cleaning system

3.1 cleaning system consists of cleaning pump, spray cleaning pipes, nozzles and other components. Angle adjustable nozzle, the jet direction can be adjusted within a range of 30 degrees. Each nozzle standoff distance ≤80mm, sprinkler piping, down, left and right have sprinkler heads to ensure that all are able to wash the surface of the workpiece.

3.2, system piping made of galvanized steel, the nozzle can be quickly replaced, disassembly, adjustable direction.

3.3 cleaning pumps with vertical booster pump, clean flow ≥30m3 / h, pressure cleaning ≥300Kpa, pressure adjustable.

4, rinsing system

4.1, rinsing system consists of rinsing the pump, spray rinsing pipes, nozzles and other components. Angle adjustable nozzle, the jet direction can be adjusted within a range of 30 degrees. Each nozzle standoff distance ≤80mm, sprinkler piping, down, left and right have sprinkler heads to ensure that all are able to wash the surface of the workpiece.

4.2, system piping made of galvanized steel, the nozzle can be quickly replaced, disassembly, adjustable direction.

4.3 rinse booster pumps with vertical centrifugal pumps, cleaning flow ≥30m3 / h, pressure cleaning ≥300Kpa, pressure adjustable.

5, compressed air systems

5.1 system consists of a control valve, blow pipes, gas nozzle, hose, fill-blowing lance and other components.

5.2, system piping made of galvanized steel, copper nozzle for the nozzle can be quickly replaced, disassembly, adjustable direction.

5.3 gas source users.

6, hot air drying system (your company without this section)

6.1 system consists of centrifugal fans, air heaters, thermostats and other components.

6.2 centrifugal fan to dry hot air circulation inside, to avoid heat loss, plus the hot air from the stainless steel (room temperature ~ 100 ℃ adjustable) blowing through the duct work conveyance and accelerate the workpiece anhydrous sulfate.

7, the filtration system

7.1, equipment cleaning liquid filtration using two filters, the first level is back to the outlet of the filter drawer baskets, the second stage filter to the pump suction port stainless steel flapper filter.

7.2, rinse the filter apparatus using two filters, the first level is back to the outlet of the filter drawer baskets, the second stage filter to the pump suction port stainless steel flapper filter.

7.3, the system has an oil cleaning device, the cleaning liquid in the waste oil separated in time, in order to extend the life cycle of the liquid. Degreasing installations scraper water separator, the slick surface of the liquid proposed separation by gravity separation method. Hourly separation capacity 30L.

8, defogging system

Automatic continuous cleaning machine pumping through the fog mist blower suction cleaning interior, through external piping efflux way.

9, electrical control system

9.1, using the relay semi-automatic control, equipment used in low-voltage electrical components are made high-quality brand-name products.

9.2 out of material end the emergency stop button is provided to prevent accidents, the timely shutdown, improve the safety performance of the equipment.

9.3, the cabinet has a two-color LED indicates normal operation, fault states.

RQX by automatic continuous cleaning machine main technical parameters:

|

Cleaning Machine Model Specifications

|

RQX40

|

RQX50

|

RQX60

|

RQX70

|

RQX80

|

RQX90

|

RQX100

|

|||||||

|

By Parts width (A)

|

400mm

|

500mm

|

600mm

|

700mm

|

800mm

|

900mm

|

1000mm

|

|||||||

|

By parts height (B)

|

250mm

|

350mm

|

450mm

|

550mm

|

650mm

|

750mm

|

800mm

|

|||||||

|

Loading height (C)

|

850mm

|

1000mm

|

||||||||||||

|

Cleaning pressure

|

3kgf/m2

|

3kgf/m2

|

5 kgf/m2

|

|||||||||||

|

Clean, rinse temperature

|

Continuously adjustable from room temperature to 80 ℃, washing liquid temperature control

|

|||||||||||||

|

Heating tank

|

Electric heating

|

|||||||||||||

|

Conveying speed

|

0—1.8m/min(stepless adjustable )

|

|||||||||||||

|

Conveyor belt carrying capacity

|

300kg/cm2

|

700kg/cm2

|

1000kg/cm2

|

|||||||||||

|

Pump flow

|

30 m3/h

|

60m3/h

|

100m3/h

|

|||||||||||

|

Tank heating steam consumption

|

0.1t/h

|

0.3t/h

|

0.6t/h

|

|||||||||||

|

Drying heating steam flow

|

------

|

-------------

|

------------

|

|||||||||||

|

Dry compressed air air consumption

|

90m3/h

|

120 m3/h

|

150 m3/h

|

|||||||||||

|

Water tank capacity

|

350L

|

1000L

|

2000L

|

|||||||||||

|

Tank electric heating, electric drying power

|

25Kw

|

100Kw

|

150Kw

|

|||||||||||

|

Gross weight

|

2100kg

|

2500kg

|

4200kg

|

4800kg

|

5600kg

|

5300kg

|

6000kg

|

|||||||

|

Dimensions (mm)

|

L

|

3000

|

3200

|

4000

|

4000

|

4500

|

5000

|

5000

|

||||||

|

B

|

1500

|

1500

|

2000

|

2500

|

2500

|

2600

|

2700

|

|||||||

|

H

|

2000

|

2000

|

2500

|

2600

|

2900

|

2800

|

2900

|

|||||||

More Through automatic continuous cleaning machine:http://www.industrial-furnace.com/furnaceaccessories/cleaning_machine.html

Pre:None ,Next:furnace lid