Copper heat treatment solution

Copper heat treatment solution

Copper heat treatment process: (Copper is made of pure copper or copper alloy in various shapes of copper including copper rods, copper wires, copper plates, copper strips, copper bars, copper tubes, copper foil, etc.) The heat treatment met

Abstract

- Promulgator: :ChengChi

- Send date:2020-05-15 15:46

Keywords:Copper heat treatment,annealing, bright,bright annealing,bright furnace,annealing furnace,bright annealing furnace,pit furnace,box furnace,trolley furnace,horizontal furnace,solution quenching,aging heat treatment,recrystallization annealing,uniform hig

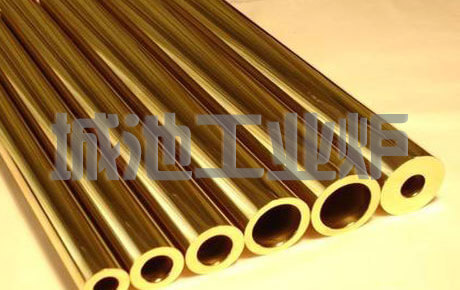

Copper heat treatment process: (Copper is made of pure copper or copper alloy in various shapes of copper including copper rods, copper wires, copper plates, copper strips, copper bars, copper tubes, copper foil, etc.) The heat treatment method of copper materials is solid Solution quenching, aging heat treatment, recrystallization annealing, high temperature homogenization annealing, low temperature stress relief annealing, low temperature strengthening annealing (such as tin phosphorus, zinc white copper).

Choice of furnace type for copper heat treatment solution: How to choose the furnace type of Chengchi industrial furnace according to the shape and number of copper materials? Small batch of copper and copper alloy pre-pump box vacuum furnace can be used. For the copper wires with large weight and high output, a bell-type vacuum bright annealing furnace can be used. From the cost performance and the lower cost of copper heat treatment, the most commonly used is the well-type vacuum bright annealing furnace. For longer and heavier copper rods, copper tubes, copper strips, copper strips, etc., it is necessary to choose a trolley-type bright annealing furnace or a horizontal vacuum bright annealing furnace. Various furnace types and related pictures are as follows:

Pre-extraction box vacuum furnace: www.industrial-furnace.com/industrialfurnaces/Chamber_Furnace/box_vacuum_furnace.html

Bell-type vacuum bright annealing furnace: www.industrial-furnace.com/industrialfurnaces/Bell_Furnace/Bell_Annealing_Furnace.html

Pit-type vacuum bright annealing furnace: www.industrial-furnace.com/industrialfurnaces/Annealing_Furnace/Pit_vacuum_annealing_furnace.html

Trolley-type bright annealing furnace and horizontal vacuum bright annealing furnace: www.industrial-furnace.com/industrialfurnaces/Atmosphere_Furnace/trolley_vacuum_annealing_furnace.html

Types of heat treatment of copper alloys

1. Homogenization annealing

The main purpose of is to eliminate the segregation of ingots during casting. The diffusion speed of the solute is proportional to the diffusion coefficient D, D = D0exp (-Q / RT), [R gas constant, Q activation energy, D0 frequency factor cm2 / s], Q means that the atom moves from one position to another The energy required for atom movement must overcome energy barriers. The activation energy of the pure phase is large and the diffusion coefficient is small, but if only the concentration is not uniform, the relative Q is small. As the temperature rises, the atoms use thermal fluctuations to overcome the increasing energy barrier. The vacancies at high temperatures also contribute to atom diffusion. Generally, the homogenization temperature is 100 ° C higher than the annealing temperature. The diffusion speed and time have a parabolic relationship: r2 = kt (r diffusion distance, k constant). Generally, the crystallization interval of tin bronze is large, and the composition is severely segregated, which requires uniform annealing.

2. Intermediate recrystallization annealing

The main purpose of is to eliminate work hardening. The intermediate annealing temperature is above the recrystallization temperature, and the degree of softening of the material depends on the cold working rate, annealing temperature, and holding time. Generally, high temperature annealing is used in the early stage of processing, and lower temperature annealing is used in the later stage of processing to ensure the uniformity of the grain size.

The empirical formula of alloy recrystallization temperature: T re = 0.4T melt (k) = 0.4t melt-164 (℃)

3. Low temperature annealing

Brass cold working produces residual stress, which can cause stress corrosion and seasonal cracking. The main purpose of low temperature annealing is to eliminate residual stress, so the low temperature annealing temperature should be as low as possible to avoid softening of the material. Low temperature annealing for tin phosphorus and zinc white copper can also significantly increase the hardness.

4. Age hardening

The purpose of aging heat treatment is to precipitate solute atoms to strengthen the alloy after solutionizing and quenching. The aging temperature is more strict, and the furnace temperature must be kept as uniform as possible.

5. Solid solution quenching

Is a heat treatment process before aging. Its purpose is to rapidly cool after holding at the solution temperature to obtain the maximum supersaturated solid solution. It is usually used together with the aging precipitation heat treatment to improve the performance of the material.

More Copper heat treatment solution:http://www.industrial-furnace.com/solution/copper_heat_treatment.html