Heat treatment process of hoist chain pin and sleeve

Heat treatment process of hoist chain pin and sleeve

Plate chain bucket elevator chain uses straight plate sleeve chain, which works under open and non-lubricating conditions and in environments where there are many mines and dust. Between the sleeve and the pin shaft and between the outer sle

Abstract

- Promulgator: :ChengChi

- Send date:2020-05-15 15:11

Keywords:Chain,pin,sleeve,heat treatment,hoist,plate chain,alloy quenched and tempered steel,42CrMo,40Cr,quenching,tempering,tempering,toughness,heat treatment process,impact toughness,tensile strength,hardenability,Yield Strength

Heat treatment process of hoist chain pin and sleeve

Plate chain bucket elevator chain uses straight plate sleeve chain, which works under open and non-lubricating conditions and in environments where there are many mines and dust. Between the sleeve and the pin shaft and between the outer sleeve and the sprocket, under external load, they rub against each other and withstand a certain amount of impact and vibration, and the large amount of foreign particles mixed between the friction pairs further aggravates the wear of the parts. Therefore, the main failure form of the pin and the sleeve is wear or breakage, which is mainly due to excessive changes in the shape and size of the sleeve and pin due to wear, which can not work normally or lead to the breakage loss caused by the pin breakage. This is the mechanical chain The main wearing parts.

1. Material selection and heat treatment process of pin and sleeve

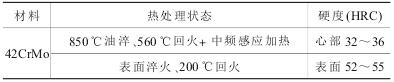

The pin and sleeve of the plate chain bucket elevator originally used 42CrMo steel, which is an alloy quenched and tempered steel of ultra-high strength steel (tensile strength? 1080 MPa, yield strength? 930 MPa), and good hardenability ( Critical diameter during oil quenching is 40 ~ 60 mm), good toughness, small deformation during quenching, no obvious temper brittleness, high creep strength and long-term strength at high temperature. After quenching and tempering treatment, it has higher fatigue limit and resistance Multiple impact capability, low temperature impact toughness is good, its heat treatment process and technical requirements are shown in Table 1. It can be seen that the mechanical properties of 42CrMo steel after heat treatment can meet the use requirements of the hoist chain and can meet the requirements of the chain's breaking strength, but the cost of material procurement and processing is relatively high, which makes the production enterprise at a disadvantage in the current fierce market competition. Therefore, using a new material to replace 42CrMo steel as the pin and sleeve material, while ensuring or improving the mechanical properties of parts while reducing production costs, is of great significance to production enterprises.

Pin and sleeve heat treatment process

Table 1 Pin and sleeve heat treatment process

Analyzed the working parameters of the NSBN series plate chain bucket elevator chain, and found that the impact is small when the working speed is 0.5 ^ -1.0 m / s, so the toughness requirements for the pin and sleeve core need not be too high. However, when the tempering temperature was 560 ℃ in the original heat treatment process, the material had a higher impact toughness, sacrificed strength, and failed to fully realize the material's performance potential.

Through the above analysis, it can be considered to use a low hardenability alloy quenched and tempered steel instead of 42CrMo. As long as the mechanical properties of this steel after heat treatment can meet or exceed the original 42CrMo mechanical properties after heat treatment.

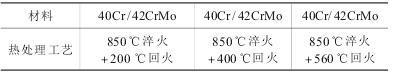

Considering the technical performance and economy of steel, 40Cr is now used as the test material, and the mechanical properties are tested under different heat treatment conditions, and compared with 42CrMo steel to verify whether their mechanical properties after heat treatment can meet the requirements of the pin and sleeve Performance requirements. The specific heat treatment process is shown in

Table 2 Pin and sleeve test materials and heat treatment process

2. Test results of mechanical properties after heat treatment

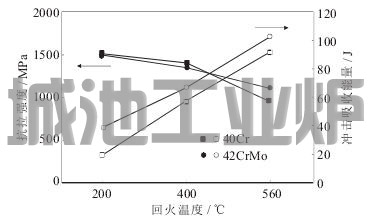

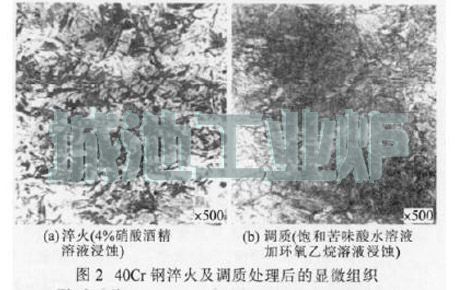

40Cr steel is one of the most commonly used low hardenability alloy quenched and tempered steels in China, and it is widely used in machinery manufacturing. After quenching and tempering, it has good comprehensive mechanical properties, good low temperature impact toughness and low notch sensitivity, and the hardenability is slightly worse than 42CrMo steel (critical diameter 20 ^ -40 mm during oil quenching). Its price is lower than that of medium hardenability quenched and tempered steel 42CrMo. According to the heat treatment process established in Table 2, 40Cr and 42CrMo steels are heat-treated. The mechanical properties of the two steels after heat treatment are shown in Figure 1. Figure 2 is the microstructure of 40Cr steel 8500Cx20min after quenching and quenching and tempering treatment.

Figure 1 Performance of 42CrMo and 40Cr after heat treatment

It can be seen from Figure 1 that the tensile strength of 40Cr steel after quenching at 850 ℃ + tempering at 400 ℃ reaches 1400 MPa, which is higher than the tensile strength of 42CrMo after quenching at 850 ℃ + tempering at 560 ℃ (1110 MPa), and then Then the medium frequency induction heating watch is quenched, and the hardness of the watch can also reach 50 ^ -55 HRC. Although the impact toughness of 40Cr steel after quenching at 850 ℃ and tempering at 400 ℃ is lower than that of the original 42CrMo after heat treatment, the toughness requirements for the pin and sleeve core are not too high, which can meet the requirements of use. From the point of view of the mechanical properties after heat treatment, under the same heat treatment process conditions, although the tensile strength and impact toughness of 40Cr are lower than 42CrMo steel, by adjusting the heat treatment process of the steel, the mechanical properties of 40Cr steel reach the original manufacturing material —The level of 42CrMo steel, it is feasible to use 40Cr steel instead of 42CrMo steel to make the pin and sleeve of the NSBN series plate chain bucket elevator chain.

Figure 2 Microstructure of 40Cr steel after quenching and quenching and tempering

3. Conclusion

According to the above test results, it is feasible to choose 40Cr steel instead of 42CrMo steel as the manufacturing material of pin and sleeve in the chain of NSBN series plate chain bucket elevator. The heat treatment process is 850 ℃ oil quenching + 400 ℃ tempering + intermediate frequency induction heating table and quenching + 200 ℃ tempering, the core hardness is 40 ^ -42 HRC, the surface hardness is 50 ^ -55 HRC, meet the requirements of use, can reduce production cost.

Based on the research results of this experiment, the NSBN series plate chain bucket elevator chain produced by Huludao Dinglida Machinery Industry Co., Ltd. has a good effect in practical use. The results of this experiment are gradually being applied and popularized.

More Heat treatment process of hoist chain pin and sleeve:http://www.industrial-furnace.com/solution/hoist_heat_treatment.html