Steel nail mesh belt continuous heat treatment production line

Steel nail mesh belt continuous heat treatment production line

The heat treatment furnace of the continuous heat treatment production line of steel nail mesh belt consists of mesh belt quenching furnace, quenching tank and mesh belt tempering furnace.This steel nail mesh belt continuous heat treatment p

Abstract

- Promulgator: :ChengChi

- Send date:2020-05-15 15:05

Keywords:Quenching furnace,mesh belt furnace,production line,heat treatment,tempering,quenching,quenching tank,continuous furnace,tempering furnace,graded quenching,industrial furnace,mesh belt

Steel nail mesh belt continuous heat treatment production line

The heat treatment furnace of the continuous heat treatment production line of steel nail mesh belt consists of mesh belt quenching furnace, quenching tank and mesh belt tempering furnace.

This steel nail mesh belt continuous heat treatment production line is often used in mechanical processing production lines to continuously quench, grade quench and temper the processed small and medium-sized parts, such as steel nails, cement nails, springs, hardware, stampings, and fastening Parts, forgings, castings, etc., the continuously processed parts are continuously transferred to the furnace mesh belt, from the inlet to the outlet, the entire quenching, grading quenching, and tempering process is completed, ensuring the consistency of the temperature of various processed parts The stability of performance and performance is an advanced equipment for the production process of steel nails, cement nails, springs, and hardware. It has been widely adopted abroad. Continuously complete cement nails, springs and other hardware parts through one production line to complete heat treatment at one time. The continuous quenching furnace, quenching tank, and tempering furnace produced by Chengchi have various parameters and technical indicators that have exceeded the advanced level of similar products at home and abroad, and have reached the advanced level abroad, and can completely replace imported equipment.

Case technical parameters

1. Rated voltage: 3 phase, 380V.

2. Rated frequency: 50HZ.

3. Rated temperature: Quenching furnace normal temperature ∽950 ℃ (adjustable).

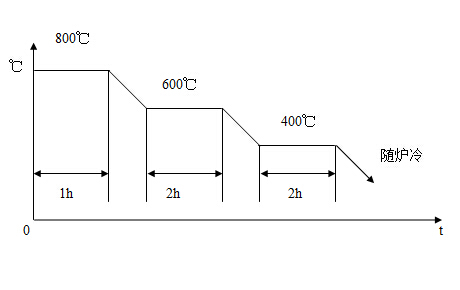

Tempering furnace Normal temperature ∽650 ℃ (adjustable).

4. Rated power:

Quenching furnace heating power: 90 KW (power size adjustable).

Tempering furnace heating power: 45KW (adjustable power)

5. Production line size: The total length of the equipment is 15.5 meters. Among them, the length of the quenching furnace is 6.5 meters (4 meters in the heating zone), the length of the quenching tank and the lifting mechanism is 2.8 meters, and the length of the tempering furnace is 8.5 meters (5 meters in the heating zone).

The quenching furnace net width is 300mm, and the furnace mouth height is 75mm (adjustable).

The tempering furnace net has a bandwidth of 500mm and a furnace mouth height of 100mm.

6. Working efficiency: Quenching (tempering) treatment: 160kg / hour.

(Note: Due to the difference in product size and thickness, the output is different).

7. Heating section: the front and back of the quenching furnace are divided into 3 zones with independent heating control,

The heating control is divided into 3 zones before and after the tempering furnace.

8. Atmosphere protection: Nitrogen or methanol drip atmosphere protection can be used in the work to achieve bright quenching treatment without oxidation of the product. (Note: The gas storage tank and other equipment should be prepared by the buyer)

9. Running speed range of mesh belt: 50mm ∽ 350mm / min.

10. Temperature control accuracy: ± 3 ℃.

11. Cooling circulating water volume of quenching tank: ≥3 tons / hour.

12. Weight of complete equipment: 9600kg

More Steel nail mesh belt continuous heat treatment production line:http://www.industrial-furnace.com/solution/steel_nail_heat_treatment.html