Aging treatment

Keywords:Aging treatment,Heat Treatment,

Aging treatment

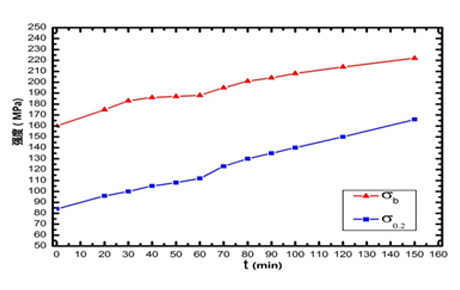

To eliminate the measuring precision molds or parts used in the long dimensions , shape changes , often at a low temperature tempering ( tempering temperature 150-250 ℃) before finishing the workpiece reheated to 100-150 ℃, holding 5 -20 hours, such as stable quality precision parts processing , called aging . In the steel member or dynamic loading conditions of low temperature aging treatment to eliminate residual stress, tissue stability and size of steel , is particularly important.

Aging treatment: solution treatment refers alloy workpiece , plastic deformation or cold casting, forging , the place at room temperature or higher temperatures to maintain its performance , shape, size change over time heat treatment process. The use of the workpiece is heated to a higher temperature and aging time than the aging treatment process , known as the aging treatment works , if the workpiece is placed at room temperature or under conditions of prolonged storage of natural aging phenomenon occurs is called the natural aging treatment . The purpose of the aging process , to eliminate the internal stress of the workpiece, the size of the organization and stability , improved mechanical properties.

Cold rolled sheet in order to ensure the stability of its performance , it does not occur within the warranty period limitation as to cause hardening of steel must overaged strip in a continuous annealing furnace overaged segment , the first occurrence of the aging effect , this allows rapid cooling after the dispersion of the carbon in the steel precipitates , this process generates a hardening of the steel sheet , with the precipitation of carbides grow , the hardness of the steel sheet reached a peak , the peak over the hardness begins to decrease , carbides grow again , the strip began over aging effects. In short , the over-aging is to make the carbides precipitated at grain within a uniform distribution of solute carbon in the steel to reduce the reduce the timeliness of the steel sheet product . Therefore, the overaging temperature is important for producing high temperature, causes the over-aging treatment after ferritic steels are still a large number of solid solution carbon , overaging poor low temperature , will reduce the carbon activity , not easy to spread.

Overaged steel will happen after the aging , but timeliness weakened, because even after over-aging treatment , cooling to room temperature ferritic matrix is still a part of a solid solution of carbon and nitrogen , over time , will change as the equilibrium slowly precipitated probably happen again kind of strain aging , I will not detail on strain aging say . In addition, to diminish the role of the carbon and nitrogen , the latter must also flat strip annealing process , the yield point of the upper and lower plates to eliminate , reduce or steel wire to slip in tensile strain marks stamping process, but over time the upper and lower yield point after still again, so there is a certain cold-rolled plate shelf life , usually six months, so the use of the unit to buy cold-rolled plate , to go through faster to use, can not place a long time

More Aging treatment:http://www.industrial-furnace.com/articles/aging_treatment.html