Residual stress annealing

Keywords: annealing,residual stress,stress annealing,stress relief,heat treatment,annealing heat treatment,relaxation annealing,annealing treatment

Residual stress annealing

In general, mechanical products always have residual stress on the processed surface. If the product is not properly annealed, it will deform under improper exposure to heat sources (such as sunlight, heat engines, etc.). The residual stress is often highly concentrated in a certain local area, such as the surface, welding area, etc., so it will locally reduce the mechanical strength of the product. To avoid these problems, we must adopt residual stress annealing.

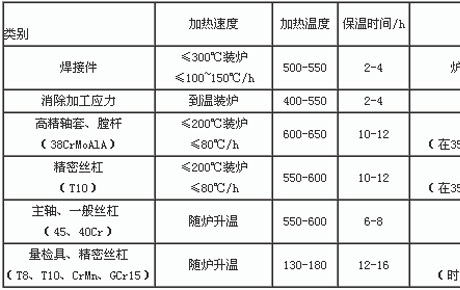

This treatment is to slowly and uniformly heat the product to a temperature below the change point, and then to this temperature for a period of time, gradually cool down slowly and evenly. In this process, the most important thing is to maintain the product area The cooling rate is the same, otherwise, after cooling, due to the difference in the cooling rate of each zone, residual stress will occur again. This is especially serious for products with complex shapes.

Because stress annealing is to use the phenomenon that atoms have a slight latent change at high temperature, to reorganize the atom position to eliminate the existence of stress. Therefore, the material stress annealing temperature varies with the high temperature creep capacity of the material. Generally for materials that are resistant to creep. For example, the annealing temperature of low alloy steel is usually 595 ~ 675 ℃, but the high chromium alloy steel is 900 ~ 1065 ℃. We can use the lower temperature and longer time to achieve the same effect as the short time and high temperature treatment of supporting stress relief as needed.

Residual stress annealing

Stress relief annealing

The main purpose of stress-relief annealing heat treatment is to remove residual stresses caused by forging, casting, machining or welding. Such residual stresses often result in reduced strength and long-term deformation of the workpiece and adversely affect the toughness and ductility of the material. Relaxation annealing heat treatment is very important for workpieces with strict dimensional longitude requirements and mechanical components with safety concerns. The heat treatment process of relaxation annealing is to heat the workpiece to an appropriate temperature below the A1 point, hold it for a period of time (not as long as the softening annealing heat treatment), and then slowly cool to room temperature. It is particularly important to note that the speed of heating should be slow, especially for large objects or workpieces with complex shapes, otherwise the effectiveness of relaxation annealing will be greatly reduced.

More Residual stress annealing:http://www.industrial-furnace.com/articles/stress_annealing.html